Select a Communication System category:

1300 Masonry mortars

All just gray?

In addition to sand, binder and water, factory-mixed masonry mortars contain further additives and admixtures in order to adjust the properties and thus achieve certain goals, such as processing time, elasticity or a thin or thick consistency.

Depending on the intended use, a distinction is made between normal mortar, thin-bed mortar and light- and medium-bed mortar.

According to the binder, a distinction is made between lime mortar, lime-cement mortar and cement mortar, each of which can absorb different compressive strengths.

In addition to the compressive strength, the material-dependent bond shear strength is important, which is achieved by optimum grading curves of the aggregates and aggregates.

For reasons of quality assurance, but also to save time, masonry mortar is nowadays hardly ever produced on the construction site.

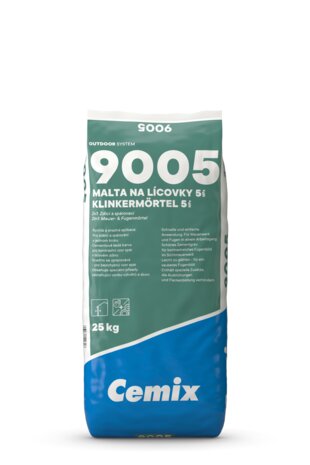

Factory dry mortar is delivered dry, ready-mixed, in storable bags and is easy to transport on the construction site. Add water, mix, allow to mature, and you're done.

For larger quantities, masonry mortar can also be supplied in silos. Please contact your Cemix representative.