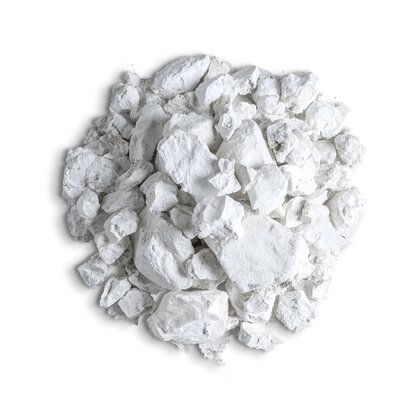

It is a white, corrosive and crystalline solid produced by calcining (burning) limestone (CaCO₃) at high temperatures (around 900-1000°C). This process is known as decarbonation and releases carbon dioxide (CO₂):

CaCO3→CaO+CO2.

Lime has a wide range of applications in industry, construction and environmental protection.

Lime for steelmaking, lump, graded from 10 to 63 MM, is produced by calcining very pure limestone with a calcium carbonate (CaCO3) content of more than 97.5% to the required parameters. Its high chemical purity, high calcium oxide content, reactivity and yield make it particularly suitable for use in the metallurgical industry.

Lime for steel production complies with standards CSN 72 2201, CSN 72 2209 and CSN 72 2235. The quality management system is ISO 9001 certified.

This material can be transported in closed Faccs wagons or trucks. Lime must be protected from moisture during transport and storage. The permissible storage period is ten days from the date of dispatch.

Lime is produced by calcining very pure limestone with a calcium carbonate (CaCO3) content of more than 97.5% to the required parameters. Due to its high chemical purity, high calcium oxide content, reactivity and yield, it is mainly used in the chemical industry for the production of carbide or fluidised lime.

Air White Lump Lime CL 90 conforms to EN 459 - 1. The quality management system is certified to ISO 9001.

The lime must be protected from moisture during transport and storage. The permissible storage period is ten days from the date of dispatch.

Our lump lime is also used in environmental protection processes to neutralise water contaminated with sulphuric acid.

Lump lime is slaked with a certain proportion of water to produce a suspension known as "lime milk".

The lime milk is dosed into the effluent using dosing pumps or other suitable equipment.

The amount of lime milk added is controlled based on the pH of the effluent and the desired resultant pH.